Shanghai’s Zhangjiang Science City recently hosted a global showdown in embodied intelligence. At the Zhangjiang Embodied Intelligence Developer Conference & International Humanoid Robot Skills Competition, Tongji University’s Dual-Arm Robotics Team dominated the industrial chain-box loading/unloading challenge with a record-breaking 4 minutes and 14 seconds, redefining speed and precision benchmarks for collaborative industrial robots.

Tackling Core Industrial Challenges: The Chain-Box Loading/Unloading Feat

This victory signifies more than speed—it marks a breakthrough in deploying embodied intelligence for real-world industrial applications. The team focused on chain-box handling, a fundamental yet critically demanding factory task repeated millions of times daily. This "simple" operation pushes robots to their limits in precision, coordination, and environmental adaptability.

"The system continuously located, grasped, and placed 6 disordered parts with positioning accuracy under 0.1mm," explained the team. Judges praised its stability and efficiency in confined spaces, confirming its practical value for replacing humans in high-repetition, harsh-environment workflows.

Triple Innovation: Redefining Industrial Precision

Vision & Sensing: Intel RealSense D435 depth cameras + visual SLAM achieved ±0.2mm positioning accuracy.

Human-like Dexterity: Realman's 7-DOF robotic arms mimic human joint structures, enabling complex maneuvers in tight spaces—prioritizing functional synergy with human workspaces over mere form.

System-Level Breakthroughs: Multi-sensor fusion (LiDAR, IMU) for dynamic environment mapping AI-driven self-learning slashed new task deployment time by 60% Impedance control for adaptive, safe grasping

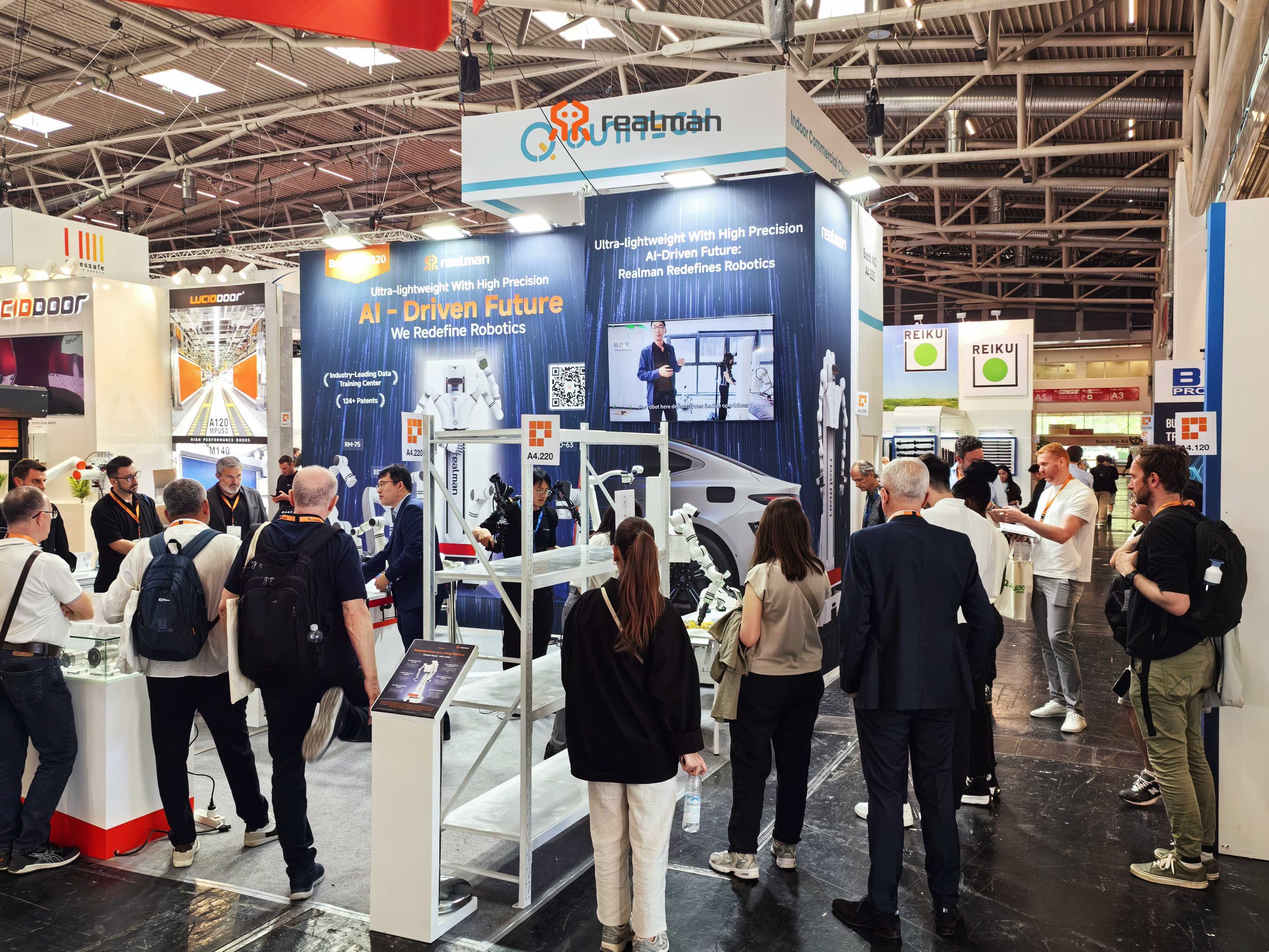

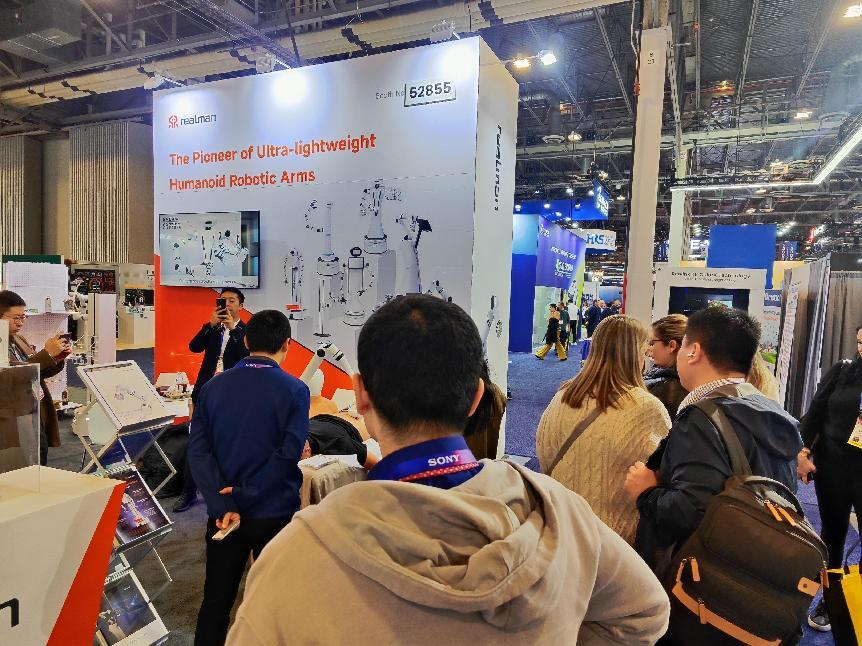

Realman’s Engineering Excellence: Raising Industry Standards

Realman Robotics’ full-stack R&D (controllers, drives, motors, harmonic reducers) delivers localized high performance:

50,000-hour MTBF (up from 50,000 hours)

CRL3 safety certification + 50,000-hour endurance validation

TÜV SÜD-certified ROHS/Reach compliance for joint modules

Progress toward IATF 16949 automotive-grade quality systems

Advanced Design: From Sequential to Collaborative Operation

The dual-arm system’s 800mm lift column handles stacked bins (4–5 layers) in space-constrained factories. Current sequential workflow:

Left arm: Identifies/grasps parts → places on inspection station

Right arm: Transfers parts to target bins

Next-gen focus: Parallel operation via synchronized arm movement. Perception ecosystem: Head-mounted global vision (±90° rotation) + 3 depth cameras (head/left/right arms) enable:

High-precision part recognition (left arm)

Process monitoring (head)

Dynamic placement planning (right arm) LiDAR-based dynamic obstacle avoidance ensures safety in unstructured environments.

From Arena to Factory Floor: Real-World Validation

Field tests addressed critical challenges:

Operation in confined spaces: Precise 3D environment modeling + virtual safety boundaries enable reliable navigation around obstacles.

2. Dynamic lighting robustness:

Hardware: Compensatory lighting at key points (e.g., arm tips)

Software: Enhanced algorithm resilience (light-invariant features, adaptive thresholds, multi-model fusion)

Zhangjiang’s Innovation Ecosystem: Industry-Academia Synergy

Tongji’s Shanghai Institute of Intelligent Science & Technology leverages Zhangjiang AI Island’s dense ecosystem:

"Opening our lab windows reveals partners’ innovations—this proximity keeps our R&D grounded in real scenarios," noted the team. Deep university-industry collaborations with nearby leaders exemplify Zhangjiang's "building-as-production-line" model.

Future Roadmap: Key Focus Areas (3–5 Years)

Multi-modal perception: Vision-force-tactile cross-modal learning

Sim-to-real transfer: High-fidelity industrial digital twins

Human-robot coexistence: Explainable intent recognition models

Autonomous long-sequence planning: Task decomposition/execution

Core challenge: Industrial constraints (dynamics, unstructured spaces, mm-level precision) versus perception/decision-making/control robustness. Key opportunity: Transitioning from fixed single-point programming to autonomous global response for flexible assembly, human-robot collaboration, and dynamic line optimization.

Conclusion

Tongji’s 4m14s Zhangjiang record transcends competition—it demonstrates how precision-engineered innovation, academia-industry synergy, and relentless real-world validation are propelling embodied intelligence into manufacturing’s core. This evolution positions the technology as the engine for next-gen industrial automation.