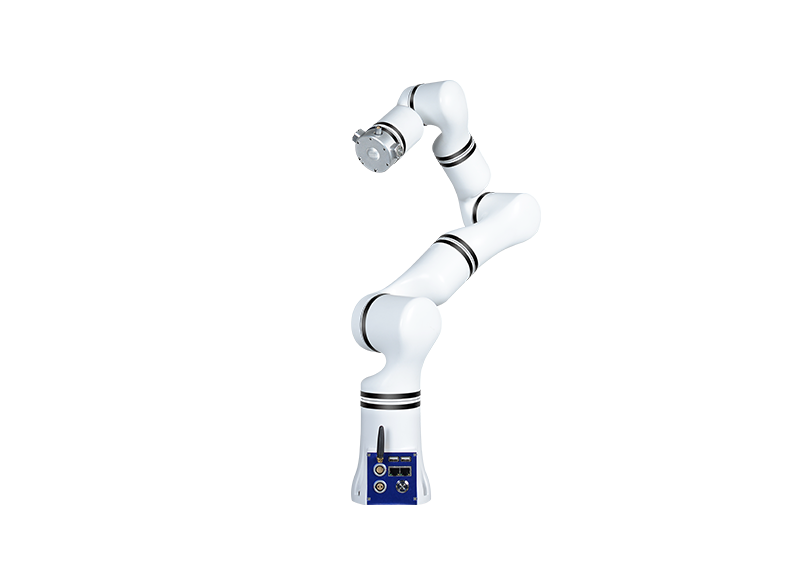

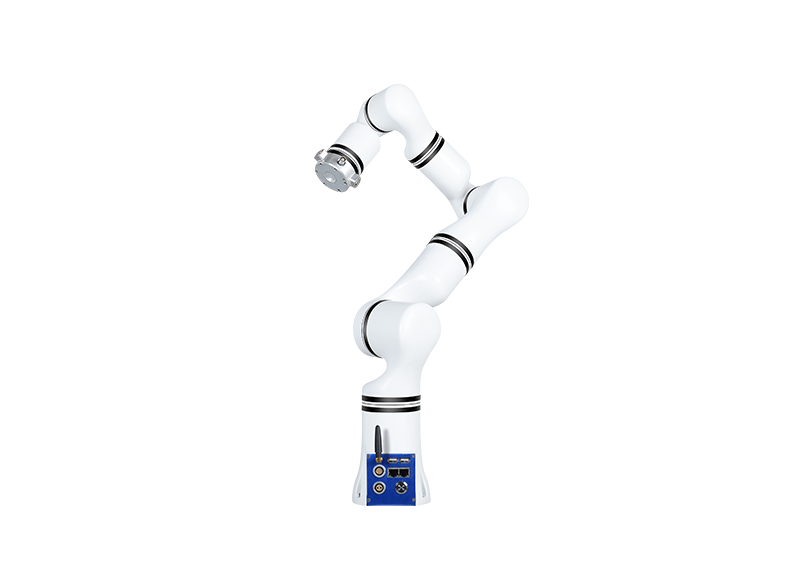

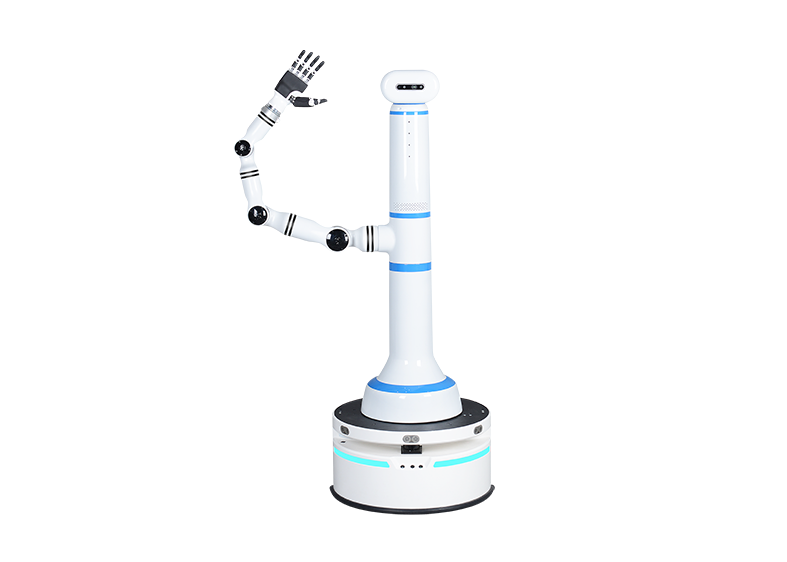

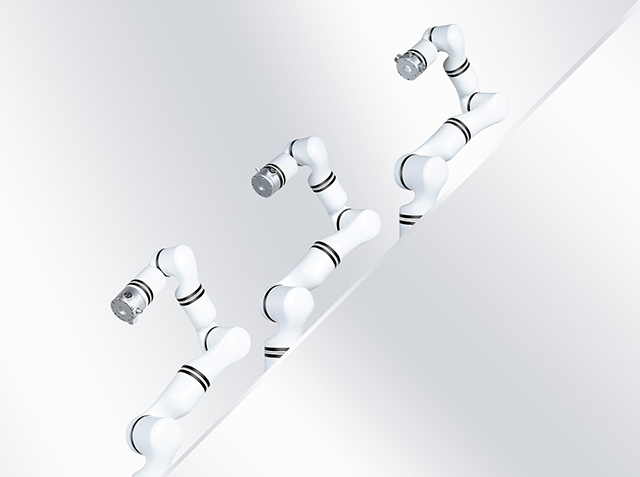

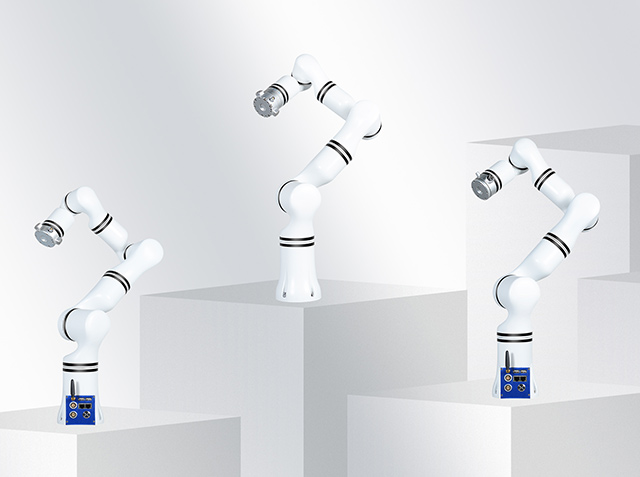

The compound robot is more refined, capable of adapting to environments of high complexity and precision, and has mobility, autonomy, and cooperation. It can complete the moving of materials, as well as join the production line to perform specific processing operations for specific types of work, which is something that non-standard automation equipment cannot do.

Advantages

Cases

Application Scenarios

Specs

Compound Robot |

||

|---|---|---|

Model |

— | |

Platform size |

Total height 1355 mm |

|

Weight |

About 53 kg |

|

Charging power supply |

Single-phase three-wire 220V ± 10% 50Hz |

|

Working voltage |

DC24V | |

Positioning accuracy |

<±5cm | |

Security protection |

Functions of laser scanning obstacle avoidance, visual obstacle avoidance, force sensors, etc. |

|

Security protection |

Network interface, USB interface, HDMI |

|

Working environment |

Temperature -10°C to +40°C, relative humidity≤85% (25°C), altitude<4000m |

|

Voice module |

— | |

Effective lifting distance |

— | |

Moving speed |

1m/s | |

Lifting speed |

— | |

Main control module |

GPU | 128-core Nvidia Maxwell |

| CPU | 4-core A57@1.43GHz |

|

Memory |

4G 64位 | |

Operating system |

Ubuntu18.04 | |

Number of network interfaces |

1 | |

Number of USB3.0 interfaces |

4 | |

Number of USB2.0 interfaces |

2 | |

Other interfaces |

GPIO、I2C、SPI、UART、I2S | |

Size |

100mm*80mm*29mm | |

Downloads

Product Manual

-

RealManProduct brochuresV2.1_EN

PDF|5.17MB

Joint Information

-

Tiny Mighty joint module Brochure V1.0_EN

PDF|2.20MB

User Manual

-

RMC-HC-01 Healthcare Robot User Manual V1.0

pdf|1.78M

-

RealMan Robotrm_exampleUser Manual V1.0

pdf|392kb

-

RealMan Robotrm_controlUser Manual V1.0

pdf|236kb

-

RealMan Robotic Arm ROS2 User Manual V1.0

pdf|624kb

-

RealMan Robotic Arm rm_moveit2_config User Manual V1.0

pdf|844kb

-

RealMan Robotic Arm rm_gazebo User Manual V1.0

pdf|260kb

-

RealMan Robotic Arm rm_driver Topic Detailed Description (ROS2) V1.0

pdf|312kb

-

RealMan Robot rm_ros_interface User Manual V1.0

pdf|184kb

-

RealMan Robot rm_driver User Manual V1.0

pdf|324kb

-

RealMan Robot rm_description User Manual V1.0

pdf|344kb

Control Software

-

RML63 V6.1.4

ZIP|51.4MB

-

RM75 V6.1.4

ZIP|48.5MB

-

RM65 V6.1.4

ZIP|49MB

3D Model

-

ECO65-B

STP|5.23MB

-

ECO65-6F

STEP|11.1MB

-

RM65-B

STEP|9.61MB

-

RM65-ZF

STEP|10.0MB

-

RM65-6F

STEP|10.0MB

-

RM75-B

STEP|9.61MB

-

RM75-ZF

STEP|10.0MB

-

RM75-6F

STEP|10.0MB

-

RML63-B

STEP|5.58MB

-

RML63-ZF

STEP|6.00MB

Dimensional Drawing

-

ECO65 dimension

PDF|36.5KB

-

ECO65 installation drawing

PDF|22.6KB

-

End Effector Installation Dimensional Drawing

PDF|28.4KB

-

Installation Dimensional Drawing of RML63 Series Robot Arm Base

PDF|22.5KB

-

RML63 dimension

PDF|27.5KB

-

Installation Dimensional Drawing of RM65, RM75 Series Robot Arm Base

PDF|21.3KB

-

RM65 dimension

PDF|73.9KB

-

RM75 dimension

PDF|76.9KB

Development Protocol

-

RealMan 6-Dof Robot JSON Protocol-V3.1

PDF|1.01MB

SDK

-

RealMan Robot Interface Function Description V3.1

PDF|805KB

ROS

-

ROS1

zip|12.34MB

-

RM65系列URDF文件

zip|8.00kb

-

ROS2

zip|2.77MB